How to choose the components for a folding door system?

On this page you will find a list of components that make up a folding door system as well as a few easy steps to selecting them. We will use the 100 series components as an example, but the main principles apply in other series as well. There are of course some exceptions in the series and if you have any questions feel free to contact our sales department or our distributors.

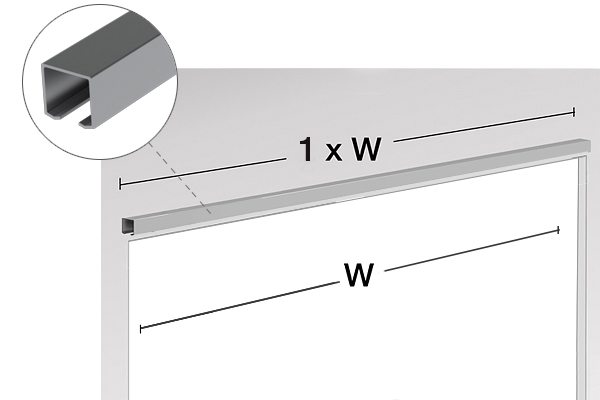

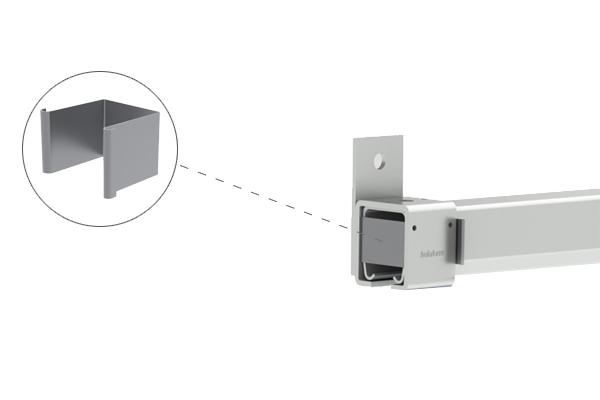

1. SLIDING TRACK

In folding door systems, the sliding track is normally the same length as the door opening.

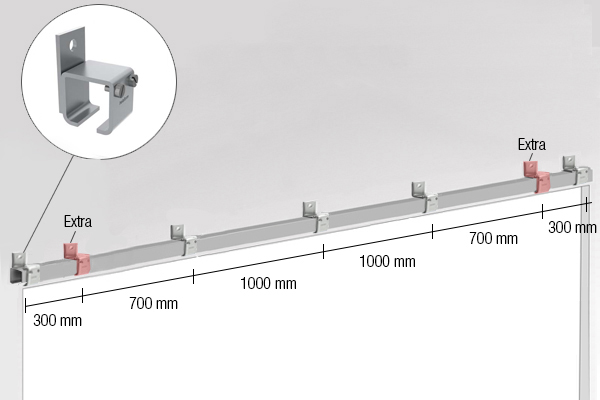

2. BRACKETS

You can choose either wall or soffit brackets. The number of brackets is chosen based on the track length. Typically, the bracket interval is 1 meter, so for example with a four meter track you need five brackets.

With folding door systems, it is necessary to add one bracket per side to the total amount, which are added to the ends of the tracks where the door leaves are stacked. The so called EXTRA BRACKET helps the folding door system to carry the additional weight that comes from the stacked door leaves. The extra bracket is installed approximately 30 cm from the end of the track.

For example: The door leaves are stacked on the right and left, two additional brackets are added (4 m track = 5 brackets + 2 extra brackets = 7 brackets)

If needed you can also join two tracks with track joints or joint brackets. Using a track joint supports the track junctions and locks the track ends together.

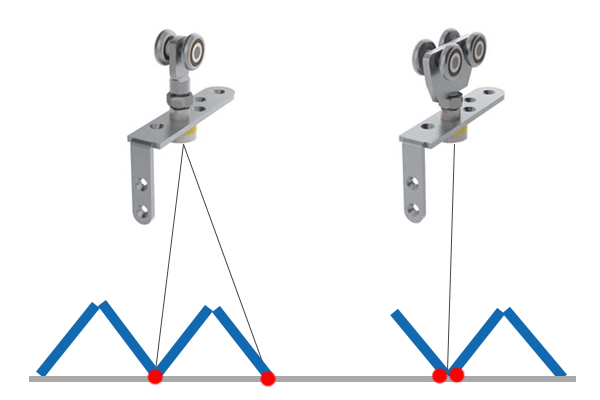

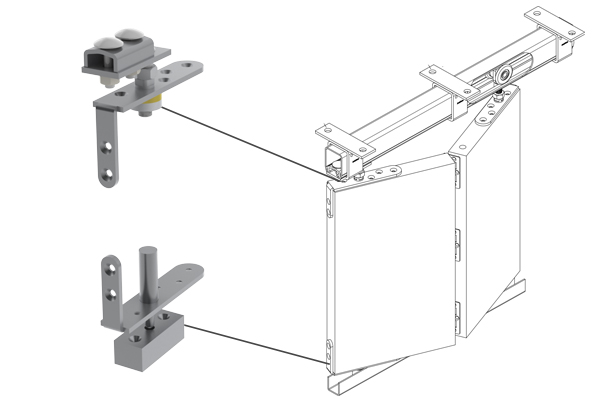

3. HANGERS AND FIXING PLATES

Hangers are installed onto every second door leaf. There are two different types of hangers: 2-wheeled and 4-wheeled hangers. All hangers have a maximum weight capacity per door leaf based on the series. 4-wheeled hangers can carry more weight than the same series 2-wheeled hanger.

If the number of the door leaves is uneven, no hangers are installed in the last door leaf . In these situations, a 4-wheeled hanger in the same series is installed to the previous door leaf that has a hanger to carry the extra weight. Uneven amount of door leaves are chosen only if it is necessary due to the size of the door leaf or if the extra uneven door leaf is used as an entrance door.

The folding door systems fixing plate is used to determine the type of folding door system. Endfolding systems requires different fixing plates then centrefolding systems or side folding systems. The door material also determines the fixing plate that should be chosen as for example metal folding doors require welding hinges (“fixing plates”) thatare already found on the metal folding door hangers body.

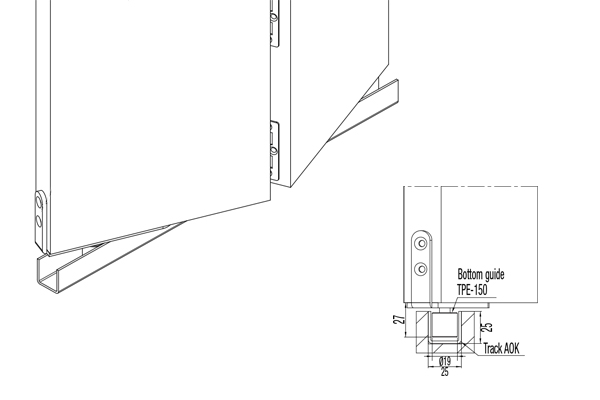

4. FOLDING DOOR BOTTOM GUIDE

Folding door systems always require a bottom guide to guide the door leaf movement. The only exception for this is light folding door systems, where there is only two door leaves per side (for example fittings set 902 and 904 assemblies). The bottom guide is installed to the same door leaf as the hanger, which means that a bottom guide is installed onto every second door leaf. A bottom guide slides on a bottom guide channel, which is installed to the floor onto the whole width of the opening.

Choosing the right bottom guide depends on the folding door system type and at the same time the fixing plate, since the installation place and fixing plate needs to be same as the hanger.

5. ACCESSORIES

PIVOT SET

Pivot set systems are used with endfolding systems. Pivot set provides a hinge like movement to the first door leaf, this means that the first door leaf does not need to be hinged and that all door leaves can be of the exact same width.

END CLIP

End clips prevent the tracks lateral movement and finish the tracks stylish design

HINGES

Welding hinges are used with metal folding doors. The amount and size of the hinges depend on the height and weight of the doors. Butterfly hinges can be used with side fixing folding door systems, since they are compatible with the hinge like hangers.

HANDLES

Flush handles and handles ease the opening and closing of a folding door system.

If any questions, you can contact our sales department or our distributors.