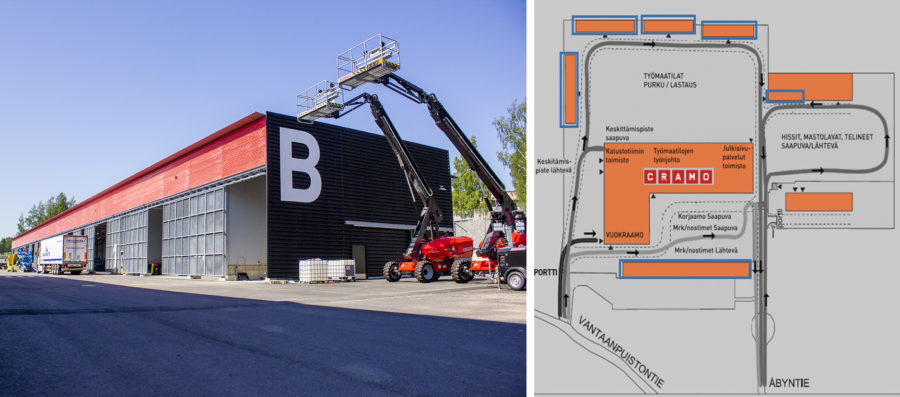

Helaform delivered the sliding door track systems to this huge logistics center for Cramo

Cramo built the one of the largest logistics center in the European rental industry in Vantaa, Finland. The total area is about 24,000 m2, of which the logistics, workshop and warehouse facilities are about 21,000 m2 and the office building about 3,000 m2. Helaform supplied sliding track systems for sliding doors in large outdoor warehouses.

Five large outdoor storage halls with a total length of more than 400 meters were built in the logistics center. The halls had to have doors that are easy to use, protect the equipment inside and that can be closed if necessary, making sliding doors the best solution for this project. There were a total of 80 heavy sliding doors in the halls. The size of one sliding door was 5000 x 5750 mm and the weight of one door was about 400 kg. Big sliding doors require durable sliding track systems, which is why Helaform stepped into the picture.

Planning and requirements

From the very beginning, Helaform worked closely with the project designer Arkkitehtiruutu Oy and the project contractor Jatke Oy. Outdoor warehouses operate e.g. as a storage place for rental machines and large rental equipment, which is why the ease of use of the doors and access to warehouses were the criteria when designing the doors. This meant that the sliding doors had to be with top-hanging systems, and there was no desire to put bottom guide tracks on the floor that could be a problem when driving over or collecting dirt over time. The bottom guiding of the sliding doors was thus implemented with wall-mounted bottom guides mounted on the support beams on the sides of the doors. This made the floor completely unobstructed and the bottom guide tracks do not need to be cleaned of any accumulating dirt.

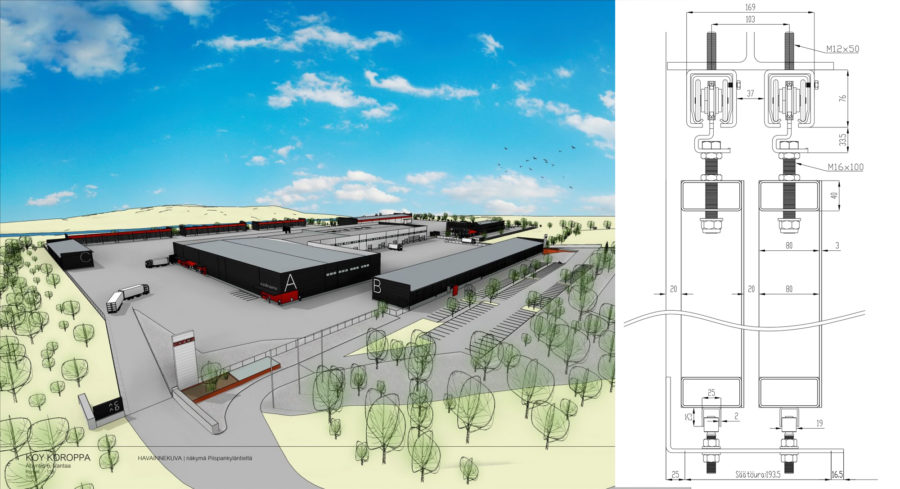

500-series sliding track system with MPS-300/500 hangers

The weight of the sliding doors determined the track system that the doors ended up being used for. The 500 Series has a load capacity of up to 500 kg, so for these 400 kg doors it was ideal choice. Two track lines came side by side (940 meters of track) and the tracks were attached to the i-beam with KK-300/500 / M12 x 50 soffit brackets. The MPS-300/500 / steel was used as the hanger in this project, because as in this case the hanger bolts were pre-installed in the doors through the frame and since the MPS hanger has “hooks” ready, the door could only be lifted and tightened into its place. Another option would have been MP-300/500 / steel where the bolt is directly attached to the hanger body that is pulled through the door frame, but then the doors would have had to be fed from the track ends to the track. And in this case, when there was no space at the sides, the MPS hanger was a better option.

Bottom guiding

Although all Helaform sliding track systems are top-hanging, proper bottom guiding must always be provided at the lower end of the sliding door. This means that the bottom guides also control the movement of the door at the bottom and prevent the doors from swinging sideways. In this project, the floor area was desired to be completely unobstructed, so AO-22 bottom guides were attached to the support beams between the openings, which slides inside the bottom guide tracks attached to the doors. Because the sliding doors themselves were quite thick and there was a desire to leave more gaps between the sliding doors than usual, Helaform made the extra-long L-bottom guide plates. This brought the bottom guides out of the support beams enough and ensured smooth operation.

Sliding doors

The sliding doors themselves were implemented so that the frame was made of 800 x 400 mm steel profile, on which came 3 mm thick steel mesh board. This structure made the sliding door really sturdy and will last for years in use. And because these were large outdoor halls over 6 m high, where wind conditions can sometimes be challenging, wind mesh load on sliding doors was minimized with steel mesh panels. Sliding doors were manufactured and installed by Anjalankosken Terästyö Oy. Helaform also worked closely with Anjalankoski, from test doors to final installations. Already in the test phase, it was commented from Anjalankoski “It is surprising to see how well a door weighing more than 400 kg slides so lightly and smoothly”.

Products use in this project:

- K-500 track (940 metres in double track)

- Soffit bracket KKL-300/500/M12x50, joint (820 pcs)

- Joint LKU-300/500/200mm (173 pcs)

- Hanger MPS-300/500/steel (180 pcs)

- Stop KP-300/500 (160 pcs)

- Bottom guide AO-22, 19 mm (with extra long bottom guide plate) (40 pcs)

- Bottom guide track AOK 3 m (471 metres)

Pictures: Helaform Oy.

3D-observation image: Arkkitehtiruutu Oy.

Do you need high quality sliding door track systems for you project?